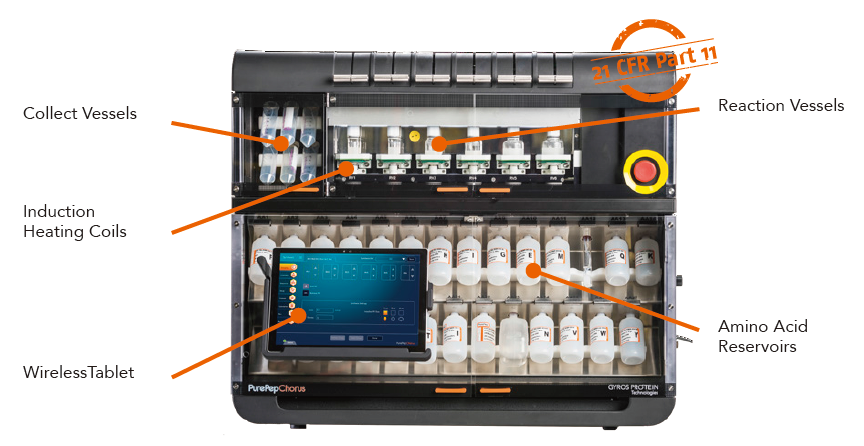

PurePep Chorus Peptide Synthesizer

UNCOMPROMISING PURITY USING A MODULAR DESIGN AND INTUITIVE SOFTWARE WORKFLOW

Pre-programmed standard methods – use as is, or as a template for customized methods

Import sequences – easily create syntheses from focused libraries

Multi-task – plan one synthesis while another is running

Auto-calculations – reagent preparation and usage calculators built into the software Configurable on all vessel pairs – rapid, independent induction heating and real-time UV monitoring Upgradeable throughput – from 2 to 4 to 6 reaction vessels

MULTI-SCALE PEPTIDE SYNTHESIZER

7 EASY STEPS TO PEPTIDE SYNTHESIS USING PUREPEP CHORUS

Step 1: Group reaction vessels to run simultaneously or sequentially. Different groups can run unique protocols.

Step 2: Input parameters including coupling methods, reagent excess, and information on resins for use in record-keeping and calculations.

Step 3: Add peptides from the library or create new ones with the sequence editor. Select cycles for special chemistry within groups and prime-free Single-ShotTM additions for expensive reagents.

Step 4: Choose to use default bottle positions for amino acids and reagents or arrange as desired.

Step 5: Assign pre-programmed or custom chemistry protocols to any cycle in any group. For heated syntheses, select default temperatures for deprotections and couplings, and exceptions for any step, cycle, RV or group.

Step 6: Let the software calculate the weights and volumes needed for all reagents, as well as theoretical yield and estimated synthesis time.

Step 7: Start synthesis from the beginning or at any cycle and step desired. View UV and temperature data in real time while a synthesis is running, and follow countdown to completion of your peptide.

IntellisynthTM UV Monitoring

Proprietary Intellisynth real-time UV monitoring can be configured on as many reaction vessel pairs as you desire, enabling automated optimization of the deprotection reaction. Monitoring the solution during mixing allows control of both reaction times and the number of repetitions, ensuring deprotections go to completion while avoiding wasted time or reagent.

View real-time UV data while a synthesis is running and full data from any completed synthesis.

Individual graphs show reaction progress during a cycle. Summary graphs indicate differences in times and repetitions between different cycles, providing valuable diagnostic information on synthetic trouble spots for difficult sequences.

Induction heating

Induction heating can be configured on as many reaction vessel pairs as you desire. It accelerates chemistry and improves purity for difficult sequences. Heating conditions in each of the six reaction vessels can be independently set to enable temperature scans for process optimization or to accommodate parallel synthesis of sequences requiring different protocols. View real-time temperature data while a synthesis is running and full profiles from any completed synthesis.

21 CFR part 11 compliance and IQ/OQ/PQ

PurePep software has been designed with 21 CFR part 11 compliance in mind, ensuring the instrument can be used in highly regulated cGMP laboratory environments. IQ/OQ support and PQ guidance are also available.

Key software features include:

User management

Electronic signatures

Audit trail

Easy-to-review reports for maximum traceability

PURITY: PurePep Pathway dedicated chemically inert pathways

PRODUCTIVITY: flexible configuration and in-lab upgradeable 2, 4, 6 RVs

POWER: independent, controlled induction heat and real-time UV monitoring

Purity starts with PurePep™ pathway inside with proprietary microfluidics that minimize cross-contamination, dead volumes, and reagent carryover.

SYSTEM SPECIFICATIONS

Number of reaction vessels:2, 4, 6 configurable with in-lab upgrades

Synthesis scale range:0.005 - 1.0 mmol per reaction vessel (6.0 mmol total for a 6 RV system)

Reaction vessel volume:Plastic, disposable - 10 mL, 45 mL;Borosilicate glass - 10 mL, 25mL, 40 mL

Number of solvent positions:8 solvents (1 to 4 L each standard, larger vessels available) 10mL, 25mL or 45 mL

Number of amino acid positions:27 amino acid bottles or Single-Shots plus six Single-Shot only positions for specialty reagents 10 mL (for standard or Single-Shot delivery for specialty reagents), 50 mL (Single-Shot only positions), 120 mL, and 400 mL sizes.

Pre-packaged and empty bottles available

Chemistries supported:Fmoc, t-Boc, organic, peptoid, combinatorial, branched, PNA

Activation:in situ and pre-activation

Fluid transfer method:Positive pressure with nitrogen

Agitation method:Nitrogen bubbling - adjustable, and/or optional

Mixing method:oscillating shaker mixing

Heating method:Controlled induction heating, configurable to the number of RVs

Cleavage:Automated on-board cleavage, separate fluid path and vent

Waste container:(1) 20 L D.O.T rated container with over-flow sensor in cap

Reporting:Real-time log of each instrument function, print to file or printer. Includes e-mail notifications to send an email to a computer or cell phone at a specified program step, at the beginning of each cycle, or if an error occurs.

Power:100-230VAC , 50/60Hz

Dimensions:87.1 cm x 72.1 cm x 72.4 cm (34.3” x 28.4” x 28.5”)

Weight:90.7 kg (200 lbs)

Warranty:One year, parts and labor

TEL:626-887-5831,909-990-7728

TEL:626-887-5831,909-990-7728 Email:ussales@molecular-lifesciences.com,info@molecular-lifesciences.com

Email:ussales@molecular-lifesciences.com,info@molecular-lifesciences.com